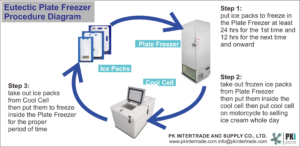

Eutectic Plate Freezer (Deep Freezer, Contact Plate Freezer, Cold Plate) – The Procedure Diagram for Ice Cream Vending Business and Cold Chain Logistics

A Eutectic Plate Freezer (also known as Deep Freezer, Contact Plate Freezer, or Cold Plate) plays a critical role in maintaining the required freezing temperatures for products like ice cream, especially in businesses like vending or cold chain logistics. These freezers ensure quick freezing, preserving the texture, taste, and quality of frozen items. Here’s a general procedure diagram for its use in the ice cream vending business and cold chain logistics.

A Eutectic Plate Freezer (also known as Deep Freezer, Contact Plate Freezer, or Cold Plate) plays a critical role in maintaining the required freezing temperatures for products like ice cream, especially in businesses like vending or cold chain logistics. These freezers ensure quick freezing, preserving the texture, taste, and quality of frozen items. Here’s a general procedure diagram for its use in the ice cream vending business and cold chain logistics.

Procedure Diagram for Ice Cream Vending Business and Cold Chain Logistics Using Eutectic Plate Freezer

- Ice Cream Production (Pre-Freezing Process)

- Milk, Cream, Sugar, and Ingredients Mixing: Ingredients are blended to create the ice cream mix.

- Pasteurization: The ice cream mix is pasteurized by heating it to kill harmful bacteria.

- Homogenization: The mixture is then homogenized for smooth texture by breaking fat molecules into small sizes.

- Cooling to the Freezing Point: The ice cream mix is cooled down to a temperature of about 4°C to prepare for freezing.

- Loading the Eutectic Plates

- Eutectic Plates: These plates are made of metal and contain a eutectic material that freezes at a particular temperature.

- Plate Pre-Cooling: The eutectic plates are pre-cooled to the freezing temperature before ice cream storage.

- Placement of Ice Cream Containers on Plates: The ice cream is placed in containers and then loaded onto the eutectic plates. The freezing plates absorb heat directly from the ice cream, rapidly lowering the temperature.

- Freezing Process

- Freezing on Contact Plates: The ice cream is quickly frozen as it is in direct contact with the cold plates. The process typically takes a few minutes to a couple of hours depending on the ice cream’s composition and the freezer’s efficiency.

- Eutectic Phase Change: The eutectic material inside the plates undergoes a phase change, solidifying into a frozen state and maintaining a constant temperature.

- Storage and Transport in Cold Chain Logistics

- Storage in Eutectic Freezer Units: Once frozen, the ice cream is stored in insulated containers and stacked in deep freezers or transport vehicles equipped with eutectic plates.

- Cold Chain Maintenance: The eutectic plates continue to maintain a low temperature during transportation. These plates retain cold for extended periods without needing constant power supply.

- Transport to Vending Locations: Ice cream is transported to vending locations, such as stores, carts, or kiosks, with minimal temperature fluctuation.

- Vending Process

- At the Vending Point: The ice cream is stored in a contact plate freezer at the vending location, keeping it frozen until served to customers.

- Serving the Ice Cream: When a customer purchases ice cream, it is served immediately. Eutectic plate freezers ensure that the ice cream remains at the ideal temperature until sold.

- Continuous Monitoring and Maintenance

- Temperature Monitoring: During the entire process, temperature monitoring is crucial to ensure that the ice cream maintains its ideal texture. Freezers equipped with temperature sensors help with this.

- Regular Maintenance: The eutectic plates and freezers must be regularly maintained to ensure efficient operation. This includes checking for leaks, ensuring proper cooling, and managing the phase change material in the plates.

Key Benefits of Eutectic Plate Freezers for Ice Cream Business and Cold Chain Logistics

- Rapid Freezing: Ensures the ice cream freezes quickly and maintains a smooth texture, crucial for ice cream’s consistency.

- Energy Efficiency: The eutectic plates store and release cold energy, reducing the need for constant refrigeration.

- Temperature Stability: The eutectic plates provide consistent cooling, which is vital for transporting ice cream long distances.

- Flexibility in Vending: Eutectic plate freezers are used in vending machines, carts, and vehicles, making them versatile for various business models.

Schematic Diagram Overview

- Ice Cream Mix Preparation (Mixing, Pasteurization, Homogenization)

- Pre-Cooling of Eutectic Plates

- Loading Ice Cream Containers onto Eutectic Plates

- Freezing Process (Rapid Freezing)

- Storage in Cold Chain Logistics (Storage Freezers, Transport Vehicles with Eutectic Plates)

- Serving from Vending Points (Vending Machines, Carts, Stores)

- Temperature Monitoring and Maintenance

This process ensures that ice cream reaches customers in perfect condition, maintaining the desired frozen texture and flavor.